Product information

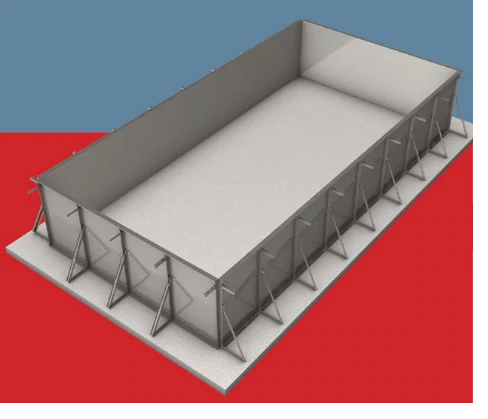

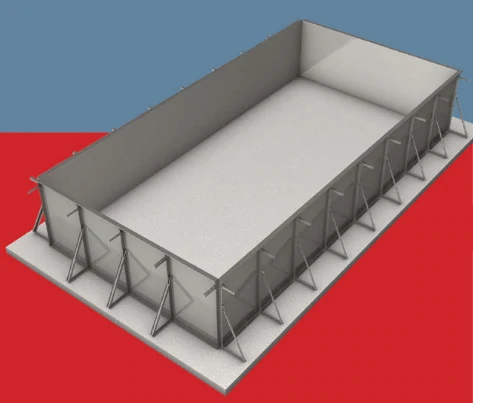

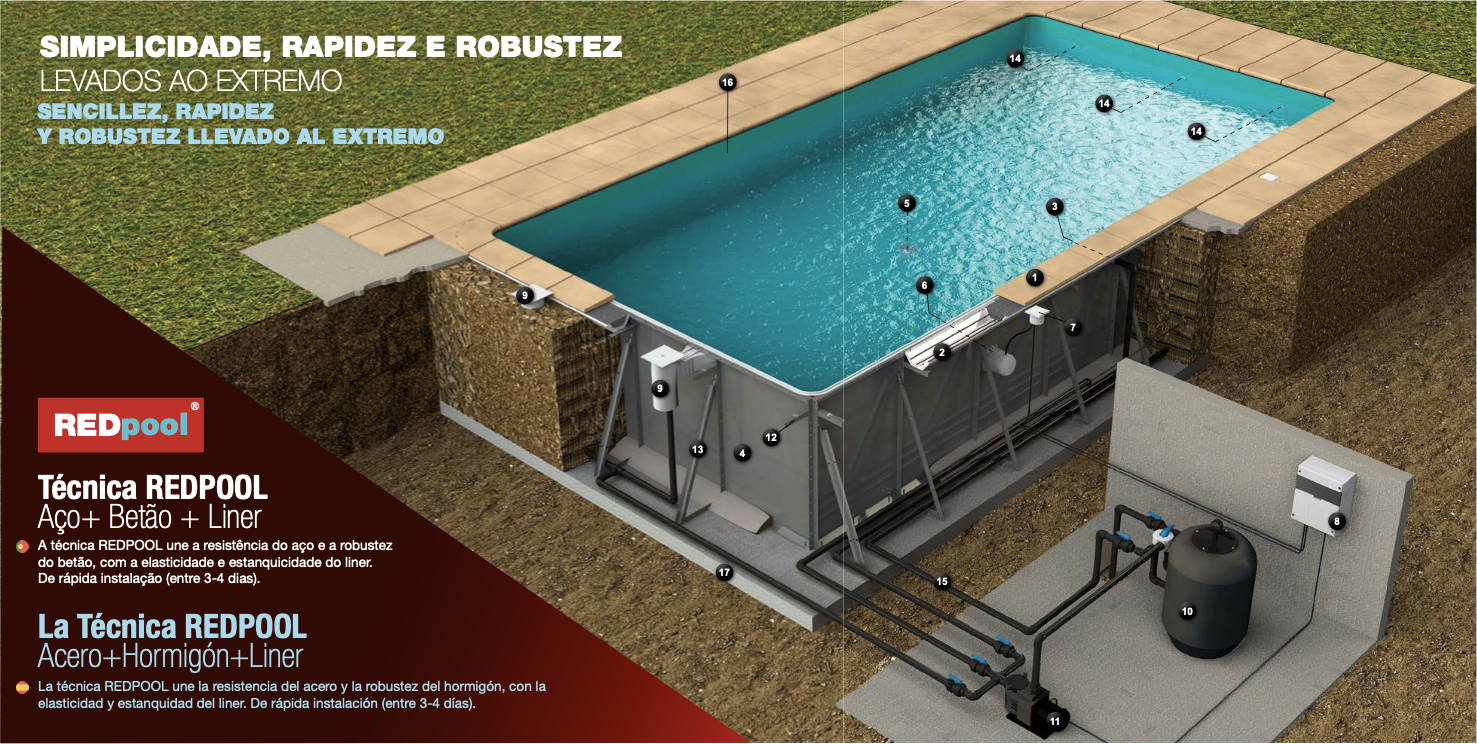

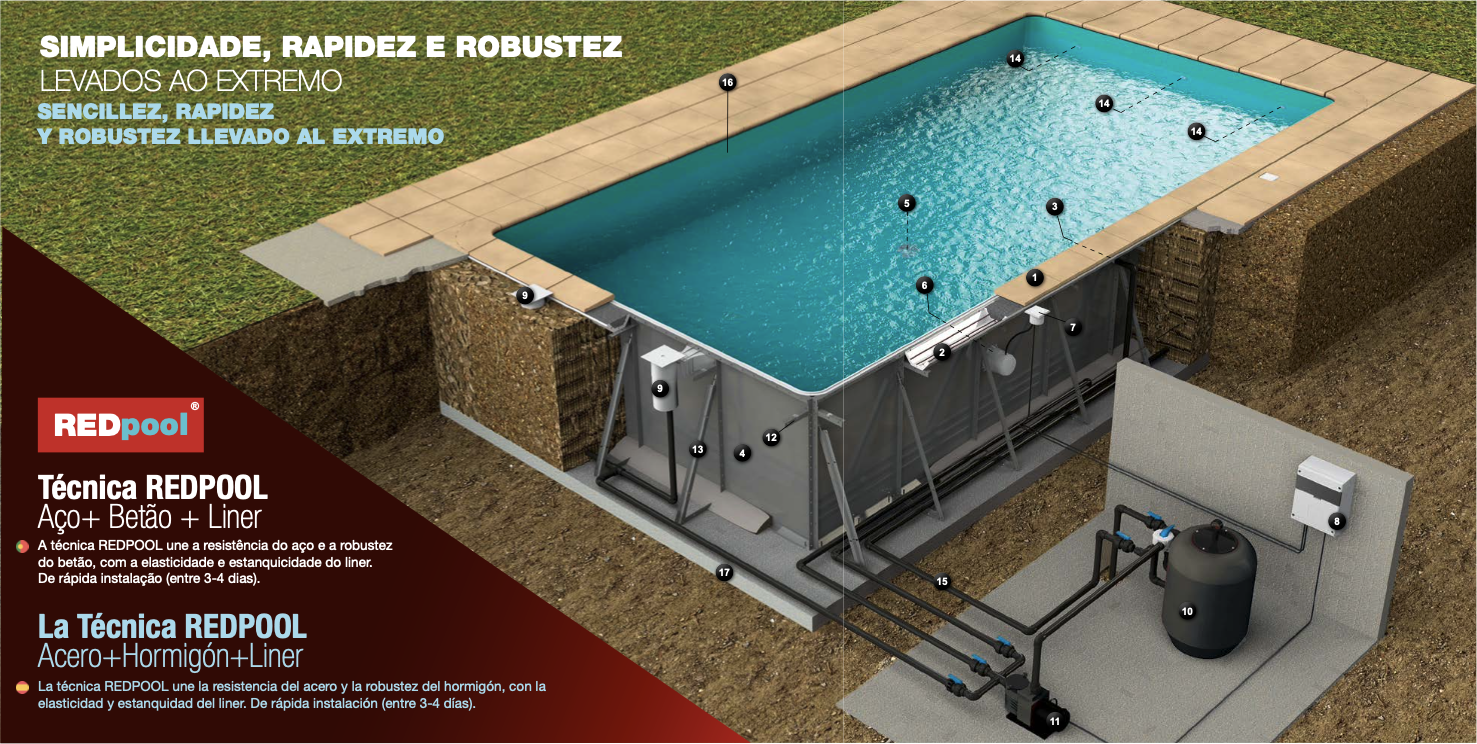

Technique Steel + Concrete + Liner

25-year guarantee on the structure and 15-year guarantee on the liner. (10% degressive guarantee per year)

The REDPOOL technique combines the strength of steel and the robustness of concrete with the elasticity and watertightness of the liner.

Quick to install (3-4 days).

Pool kit includes:

- STANDARD STRUCTURE KIT - Complete structure in 2 mm thick STEELPANEL steel, composed of:

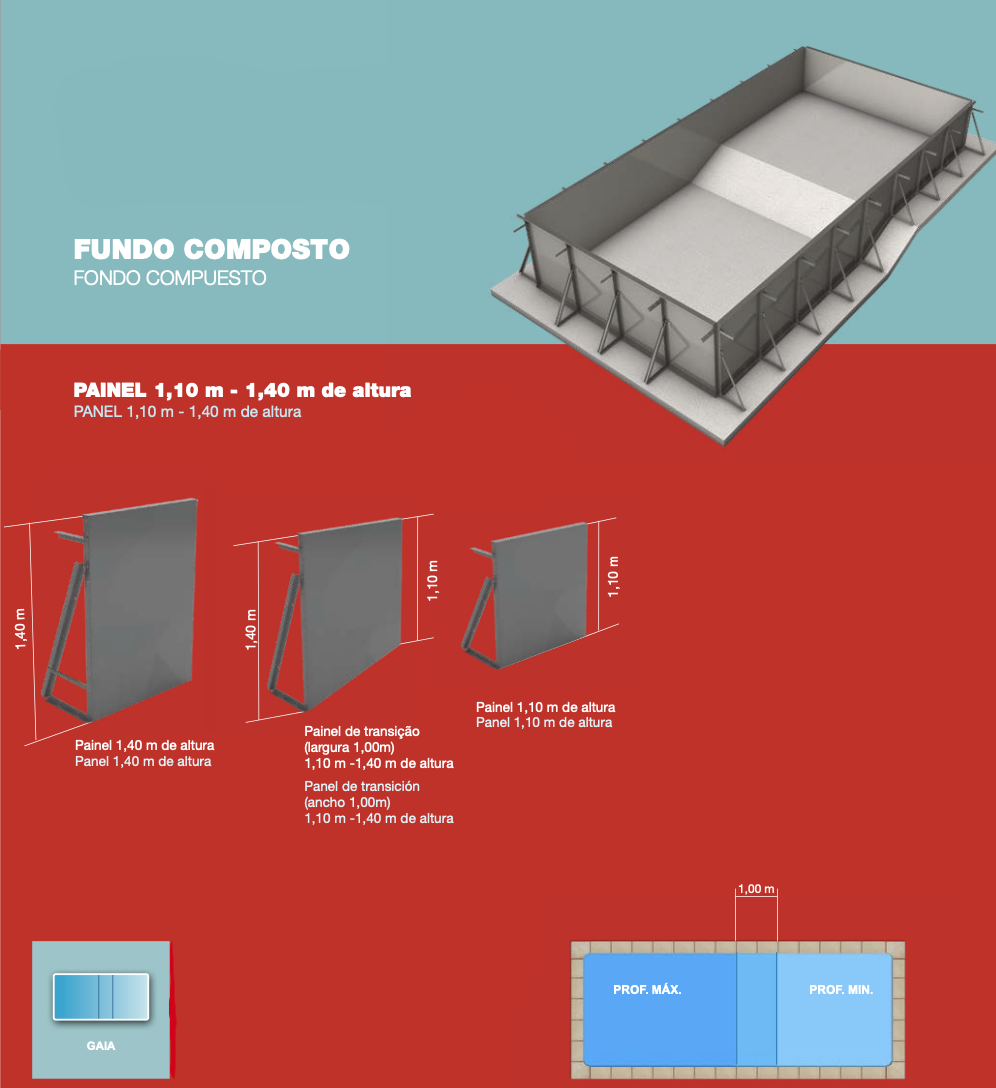

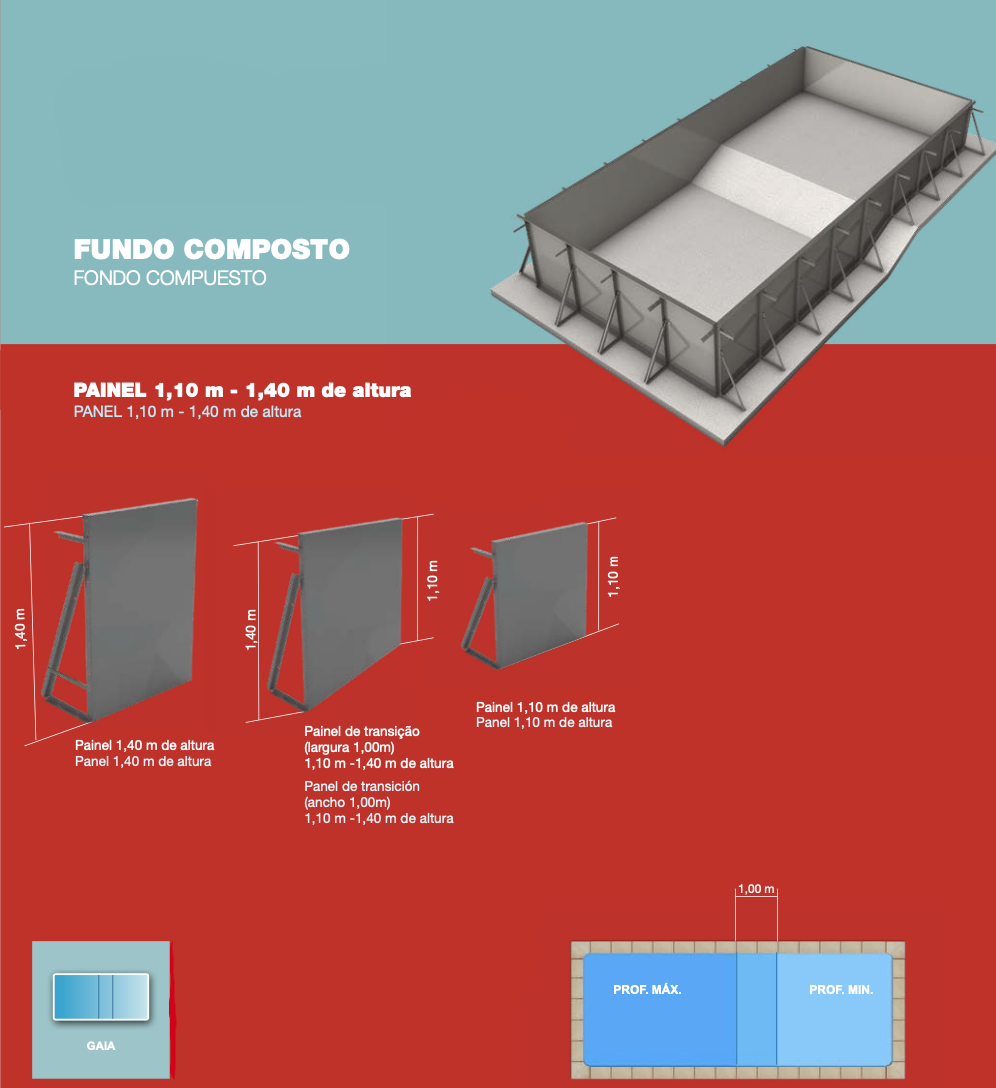

- Steel panels 1.4mt and 1.1mt high and 1mt long.

- Props

- Galvanized nuts and bolts

- Aluminum tape

- OPTIONAL: Edge gutter

- Liner 75/100 which includes: (OPTIONAL)

- Liner plain colour 75/100

- PVC Hung profile and respective corners to fix the liner

- Locking joint

- Self-drilling screws

- Liner in reinforced fabric including (OPTIONAL)

- Smooth reinforced screen 150/100

- Hung PVC profile and respective corners to fix the liner

- Locking joint

- Self-drilling screws

- Recessed material (Recessed), which includes:

- A400 Skimmer

- Reflux (impulsion mouth)

- Suction socket

- Bottom drain

- Projector 12V 300W

- Connection box

- Filtration system, OPTIONAL included in the INSTALLATION, includes:

- Sand filter

- Self-priming pump with prefilter

- Electric panel with transformer and 30mA differential

- Accessories, OPTIONAL included in the installation, include

- Telescopic pole

- Manual aspirator

- Floating tube

- Chlorine-ph analysis kit

- Thermometer

- Amanha leaves

- Camaroeiro

- Wall brush

- Installation of panels and engine room (OPTIONAL)

- Edging: Edging kit GRANITUS model (OPTIONAL) - Does not include application

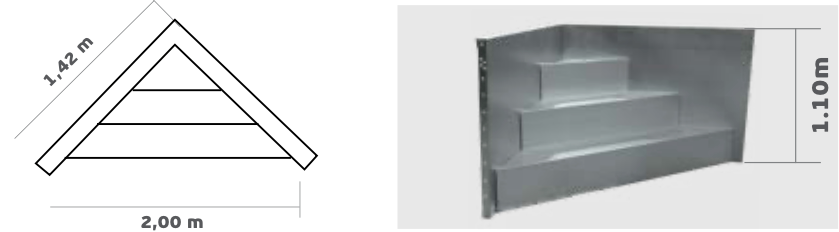

- Interior corner stairs (OPTIONAL)

- Underground case for technical place (OPTIONAL)

- Surface casing for the technical room (OPTIONAL)

Does not include:

Excavation (estimated value of 500€ with a local excavation company and if there is direct access to the pool site by machinery)

Civil construction of the slab of the measure corresponding to the pool in composite bottom as explained below. (values between 650€ and 1200€ in a local construction company)

Civil construction of the technical room

Laying of water, sewage/rainwater and electricity in the technical room.

Placing concrete/cement on the outside corner between the panel and the existing concrete slab. (mandatory)

Grounding of pool (Placing earth around the panels before filling the pool with water.

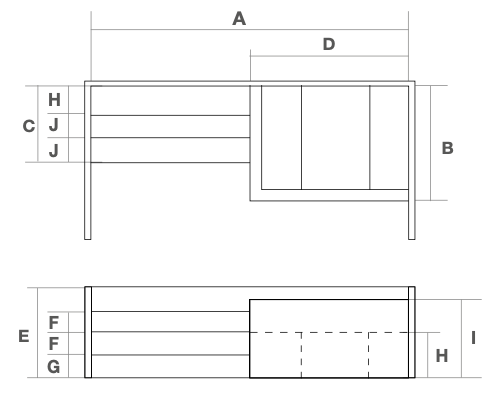

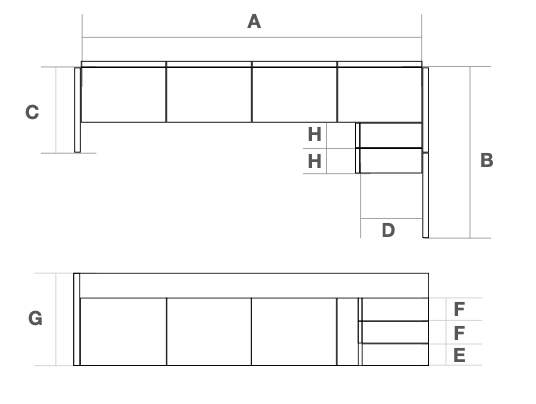

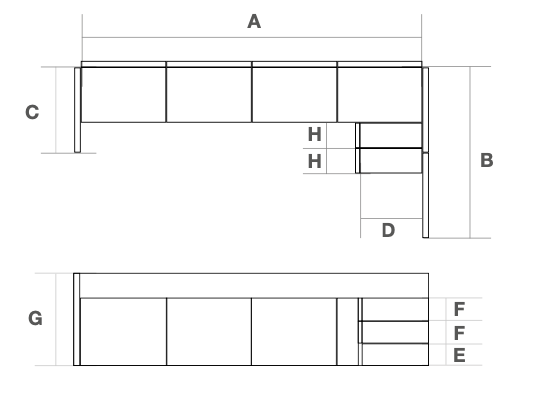

Pools available in the following sizes

5,00x3,00mts

6,00x3,00mts

7,00x3,50mts

8,00x4,00mts

9,00x4,00mts

10.00x4.00mts

10.00x5.00mts

11.00x5.00mts

12,00x6,00mts

Installation:

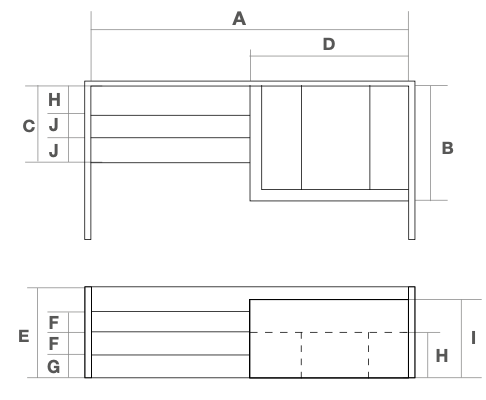

It is possible to buy the pool and installation, to do the installation it is necessary to have a flat concrete base on the periphery of the pool with a minimum of 0.5 outside the pool area and already existing place with a curing period of more than 1 week.

Application of the panels on the slab with chemical dowel

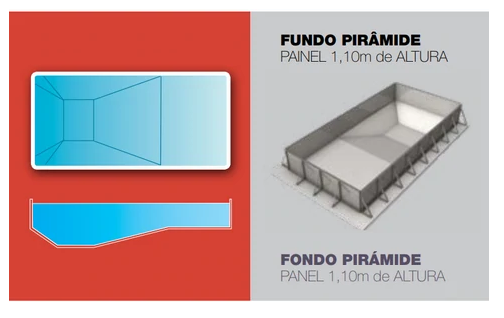

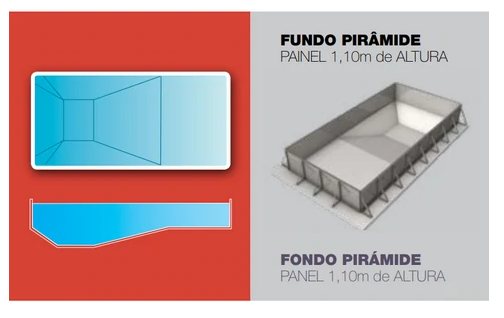

Types of slabs:

- Flat Bottom, account for an extra 0.5mt all around the pool, example: 6x3 pool, the slab should be 7x4.

- Pyramid Bottom, on the periphery the pool should be all aligned and descend in the centre of the pool, example: 8x4 pool, the slab should be 9x5.

- Composite Bottom, on the bottom there are two different levels, one with the deepest level and another with the shallowest level, the transition should be done with a 1mts ramp.

NOTE: All pools are supplied with a 1,1 mt height panel but the pool depth can have a maximum of 2,0 mts with a composite or pyramid bottom.

OPTIONALS AVAILABLE:

- Liner lining

- Liner Lining

- Swimming pool border

NOTE: The Base pool does not have Lining

Characteristics detailed in the photographs:

1- Carrying out the Excavation

Due to its importance, it should be done conscientiously. Under normal conditions it is done in one day.

2- Concrete work

The slab must have a completely smooth finish, free of irregularities, with an average thickness of 10/15cm.

3-Fixing of Panels

The steel panels are mounted directly on the bottom slab. After being bolted, they are levelled and plumbed.

4-Laying the coping

After the backfill, a concrete strap is made to place the border.

5-Fitting the Liner

Completely computer-designed, without limitations, it adjusts perfectly to any model. The liner is installed in just a few hours.

6- Connecting the Machines

After all piping is done, the connection of the filtration equipment in the engine room is usually done on the day of the filling.

Produtos recomendados

- Choosing a selection results in a full page refresh.